Repetitive Manufacturing - Overview

What is Repetitive Manufacturing?

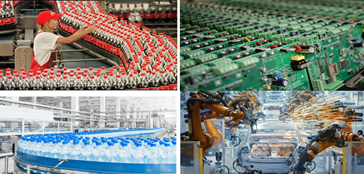

Repetitive Manufacturing is used for the production of standard products that are produced in large quantities in a continuous flow. Repetitive manufacturing is the production of goods in rapid succession. Goods that are created through repetitive manufacturing follow the same production sequences. Repetitive manufacturing often goes hand-in-hand with automated assembly processes.

Repetitive manufacturing is used when the production process is a continuous, and steady stream of demand. This demand must be met using minimal administrative effort, but with real-time insight and control of the process.

There is reduced control effort (no status procedure) and a period-based cost controlling. A raw material for production is consumed and product delivered, there is lesser time wastage.

Important element of repetitive manufacturing is production schedules, where production orders are consolidated into schedules. Another important consideration for generation of schedule is capacity of bottleneck work center. On completion of schedule run, completed units are moved to inventory and lot/serial number is assigned. Repetitive manufacturing enables you to specify a rate schedule by effective date in daily, weekly, or monthly quantities.

Characteristics of Repetitive Manufacturing

- Production volume is stable and predictable.

- Lead time is short.

- Factory layout is product-oriented and often characterized as cellular manufacturing in which dissimilar operations are physically grouped so that the product flows rapidly from one operation to the next.

- Setups are short so that switching between products does not significantly affect the time that is available for production.

- Group technology is often incorporated into the design engineering and manufacturing engineering to accommodate some variety with little effect on cost or production speed.

- Unit of measure if often “each”.

Difference between Discrete and Repetitive Manufacturing

Discrete Manufacturing

1. Order Based Production (Individual Production Orders)

2. Product change frequently

3. Varying sequence of work centers (Complex routings)

4. Semifinished products often put into interim storage

5. Components staged with reference to order

6. Status processing

Repetitive Manufacturing

1. Period Based Production (Production with certain quantities per period)

2. Product produce unchanged over a long period of time.

3. Steady Flow through Production (Simplified routings)

4. Semifinished products often directly processed without interim storage.

5. Components are staged at line periodically and anonymously.

6. Reduced control effort (no status procedure)

Our next blog will talk more on what are the scenarios of high volume production industries, adavntages and benefits of repetitive manufacturing and ERP context with repetitive manufacturing.